Pultruded Composites: A Design and Material Engineer's Guide

This guide will explore the benefits, drawbacks, and target applications of pultruded composites

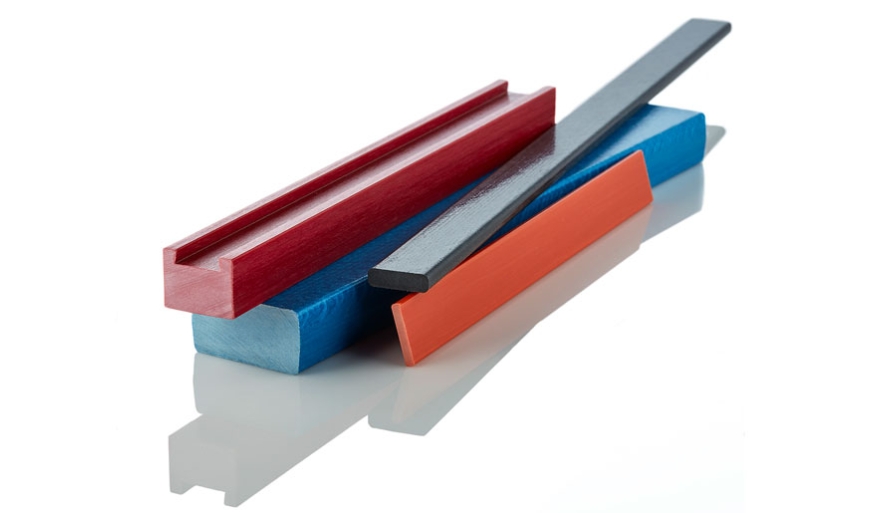

Pultruded composites are a type of high-performance, fiber-reinforced polymer (FRP) composite material that are manufactured using a continuous process called pultrusion. Here, continuous fibers, such as glass or carbon, are pulled through a thermoset resin bath, such as epoxy, polyester, or vinyl ester, and then formed into a desired shape using a die. The resin is then cured, resulting in a strong, lightweight, and durable composite product.

FRP pultrusions offer several advantages over traditional materials, like metals, ceramics, and unreinforced plastics. They have the unique ability to be custom-designed to meet specific product needs. Trying to decide whether pultruded composites are ideal for an application? Consider the benefits, drawbacks, and target applications suitable for this technology.

Advantages and Disadvantages

Benefits of incorporating pultruded composites include:

- Manufacturing Efficiency: Pultrusion is a continuous process that provides benefits over alternative composite manufacturing methods such as high volume output, lower costs, and faster lead times.

- High strength and stiffness-to-weight ratio: Pultruded composites are strong and stiff, yet they are also lightweight. Carbon fiber pultrusions are exceptionally lighter than metal and other materials. This makes them ideal for applications where weight savings is important, such as aerospace, automotive, and transportation.

- Corrosion resistance: FRP composites are highly resistant to corrosion, making them well-suited for applications in industries, such as chemical processing, marine, and oil and gas.

- Electrical insulation: Fiberglass pultrusions can be engineered to be non-conductive, making them ideal for electrical applications where dielectric properties are required.

- Dimensional stability: Pultruded composites will not warp or crack* over time. This is important in applications where precise tolerances are required.

- Custom engineered: Pultrusions can be manufactured in a wide variety of shapes and sizes, including rods, tubes, and beams, as well as more complex profiles. They are also highly customizable. Materials and processes such as fiber type, fiber volume, resin type, and surface veils and treatments can be engineered to meet specific properties and application requirements.

Drawbacks of using pultruded composites include:

- Limited geometry: Pultruded composites are limited to constant or near constant cross-section components. This is because of the continuous manufacturing process in which the fiber-reinforced material is pulled through the forming die.

- Higher manufacturing component cost: The molds and dies used in pultrusion can be expensive. This is because the molds must be made of higher quality materials, must be able to withstand the heat and pressure of the pultrusion process, and be produced according to tight machining tolerances.

- Low transverse strength: Pultruded composites can have lower transverse strength than longitudinal strength. This means that they are weaker in the direction perpendicular to the fibers. However, this can be overcome by incorporating multiaxial fabrics or fibers into the pultrusion process.

- Pultruded composites can be difficult to repair if they are damaged. The entire component may need to be replaced, which can be expensive and time-consuming.

It is important to weigh the advantages and disadvantages of pultruded composites before deciding whether they are right for your application. If you need a material with high strength and stiffness-to-weight ratio, corrosion resistance, and a constant cross section, then pultruded composites are a good option to consider. However, if you need a composite material with high transverse strength or a complex geometry, then you may need to consider other options.

How to Choose the Right Pultruded Composite for Your Application

When choosing a pultruded component or profile for your application, it is important to consider the following factors:

- Mechanical property requirements: What are the strength, stiffness, and shear requirements for the application?

- Environmental requirements: Will the composite be exposed to harsh environmental conditions, such as chemicals, salt water, or extreme temperatures?

- Weight requirements: Is weight savings important for the application?

- Cost requirements: What is the budget for the application?

An experienced pultrusion manufacturer can offer design and formulation expertise, and work with you to develop the right pultruded composite for your application.

Consider the Target Applications

Pultruded composites are used in a wide variety of applications, including:

- Aerospace: aircraft and spacecraft components, such as control surfaces, landing gear, and structural supports.

- Automotive: automotive components, such as drive shafts, bumpers, and suspension components.

- Infrastructure: infrastructure reinforcement and components, such as railroad ties, bridge decks, concrete repair and reinforcement, utility poles, electrical insulators, and cross arms.

- Chemical processing: chemical processing equipment, such as pipes and floor grating.

- Medical: brace stiffeners and endoscopic dissectors rods.

- Marine: marine applications such as masts, battens, dock whips, retaining walls pilings, anchor pins, and docks.

- Oil and gas: oil and gas applications, such as wellheads, pipelines, sucker rods, and platforms.

- Wind energy: wind turbine blade components, such as blade reinforcements, spar caps, and root stiffeners.

- Sporting goods: components requiring a constant cross-section such as skis, poles, golf equipment, paddle shafts, archery components, and tent poles

Pultruded composites offer a number of advantages over traditional metals and plastics. If you are a design materials engineer looking for a high-performance composite material for your application, pultruded composites are a good option to consider.

Contact us to connect with one of our composites engineers, or explore GlasForms™ Pultruded Rods, Tubes & Custom Profiles here.

*Properly designed pultruded composites will not warp or crack over time.